Ansi Asq Z1 9 2008 Pdf Free

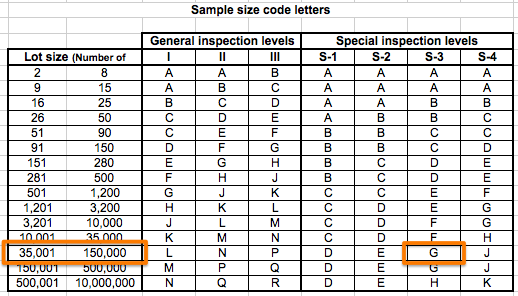

AQL_table_limits.png' alt='Ansi Asq Z1 9 2008 Pdf Free' title='Ansi Asq Z1 9 2008 Pdf Free' />Acceptance sampling uses statistical sampling to determine whether to accept or reject a production lot of material. It has been a common quality control technique. Knowledge Center Learn About Quality Social responsibility History. In a modern context, the history of social responsibility can be traced to a now infamous. The acceptable quality limit AQL is the worst tolerable process average mean in percentage or ratio that is still considered acceptable that is, it is at an. Listing of standards covering attribute and variables acceptance sampling plans inclusing military, ANSI, and ISO standards. MILSTD105, Sampling Procedures and Tables for Inspection by Attributes, is another of those popular military standards that got cancelled during Mil Spec reform. Training Calendar Quality Productivity Solutions, Inc. Course No. 1. 55. This course is designed to present DOE principles and to provide hands on experience with designs and applications. Course Benefits. Attendees will learn to Understand and apply DOE principles Design experiment using full, 2. K factorials, and other designs. Ansi Asq Z1 9 2008 Pdf Free' title='Ansi Asq Z1 9 2008 Pdf Free' />

Military Handbooks And Standards Plus NASA and Nuclear Regulatory Commission Documents Pertaining To Reliability And Life Cycle Cost. Analyze experiments using response surface methods Screen X factors to define vital few Establish relationship between Ys and Xs. Prerequisites Basic statistics background. Duration Three Days. Cost 1. 29. 5 Includes materials and certificate of attendance Topics Covered Module 1 Introduction DOE. DOE principles, design types, applications and terminology. Module 2 DOE roadmap. DOE methodology, developing roadmap, factorslevels, blocking, replications. Module 3 DOE with Minitab. Fit a full model to data, effects activenon active, factorial plots, models, practices on Minitab. Module 4 Factorial designs. Factors and Interactions, advantages and disadvantages, factorial designs for 2 levels and more than 2 levels, main effects and interactions. Module 5 Fractional factorial experiments. How to reduce number of runs, confounding, resolutions, design generators and alias structures. Module 6 Response surface methodology. Different types, optimization, central composite design Who Should Attend This course is designed for individuals and managers who endeavor who wants to learn how to apply DOE. For More Information Contact the Training Administrator infoqpsinc. Toll Free 1 8. 77 9. Ansi Asq Z1 9 2008 Pdf Free' title='Ansi Asq Z1 9 2008 Pdf Free' />Note This course is also available for training onsite. A discount is available when 6 or more attendees enroll. Business Solutions Providers for Quality, Productivity and Performance Excellence. Experts in Lean Six Sigma, Management System, Supply Chain, Project. Management and Professional Development. PMI, PMP. RMP, ACP, CAPM, CBAP, SP, and PMBOK are registered marks of the Project Management. Acceptable quality limit Wikipedia. The acceptable quality limit AQL is the worst tolerable process average mean in percentage or ratio that is still considered acceptable that is, it is at an acceptable quality level. Closely related terms are the rejectable quality limit and rejectable quality level RQL. In a quality control procedure, a process is said to be at an acceptable quality level if the appropriate statistic used to construct a control chart does not fall outside the bounds of the acceptable quality limits. Otherwise, the process is said to be at a rejectable control level. Texas Auto Direct. In 2. 00. 8 the usage of the abbreviation AQL for the term acceptable quality limit was changed in the standards issued by at least one national standards organization ANSIASQ to relate to the term acceptance quality level. It is unclear whether this interpretation will be brought into general usage, but the underlying meaning remains the same. An acceptable quality level is a test andor inspection standard that prescribes the range of the number of defective components that is considered acceptable when random sampling those components during an inspection. The defects found during an electronic or electrical test, or during a physical mechanical inspection, are sometimes classified into three levels critical, major and minor. Critical defects are those that render the product unsafe or hazardous for the end user or that contravene mandatory regulations. Major defects can result in the products failure, reducing its marketability, usability or saleability. Lastly, minor defects do not affect the products marketability or usability, but represent workmanship defects that make the product fall short of defined quality standards. Different companies maintain different interpretations of each defect type. In order to avoid argument, buyers and sellers agree on an AQL standard, chosen according to the level of risk each party assumes, which they use as a reference during pre shipment inspection. See alsoeditReferenceseditFurther readingedit.

Military Handbooks And Standards Plus NASA and Nuclear Regulatory Commission Documents Pertaining To Reliability And Life Cycle Cost. Analyze experiments using response surface methods Screen X factors to define vital few Establish relationship between Ys and Xs. Prerequisites Basic statistics background. Duration Three Days. Cost 1. 29. 5 Includes materials and certificate of attendance Topics Covered Module 1 Introduction DOE. DOE principles, design types, applications and terminology. Module 2 DOE roadmap. DOE methodology, developing roadmap, factorslevels, blocking, replications. Module 3 DOE with Minitab. Fit a full model to data, effects activenon active, factorial plots, models, practices on Minitab. Module 4 Factorial designs. Factors and Interactions, advantages and disadvantages, factorial designs for 2 levels and more than 2 levels, main effects and interactions. Module 5 Fractional factorial experiments. How to reduce number of runs, confounding, resolutions, design generators and alias structures. Module 6 Response surface methodology. Different types, optimization, central composite design Who Should Attend This course is designed for individuals and managers who endeavor who wants to learn how to apply DOE. For More Information Contact the Training Administrator infoqpsinc. Toll Free 1 8. 77 9. Ansi Asq Z1 9 2008 Pdf Free' title='Ansi Asq Z1 9 2008 Pdf Free' />Note This course is also available for training onsite. A discount is available when 6 or more attendees enroll. Business Solutions Providers for Quality, Productivity and Performance Excellence. Experts in Lean Six Sigma, Management System, Supply Chain, Project. Management and Professional Development. PMI, PMP. RMP, ACP, CAPM, CBAP, SP, and PMBOK are registered marks of the Project Management. Acceptable quality limit Wikipedia. The acceptable quality limit AQL is the worst tolerable process average mean in percentage or ratio that is still considered acceptable that is, it is at an acceptable quality level. Closely related terms are the rejectable quality limit and rejectable quality level RQL. In a quality control procedure, a process is said to be at an acceptable quality level if the appropriate statistic used to construct a control chart does not fall outside the bounds of the acceptable quality limits. Otherwise, the process is said to be at a rejectable control level. Texas Auto Direct. In 2. 00. 8 the usage of the abbreviation AQL for the term acceptable quality limit was changed in the standards issued by at least one national standards organization ANSIASQ to relate to the term acceptance quality level. It is unclear whether this interpretation will be brought into general usage, but the underlying meaning remains the same. An acceptable quality level is a test andor inspection standard that prescribes the range of the number of defective components that is considered acceptable when random sampling those components during an inspection. The defects found during an electronic or electrical test, or during a physical mechanical inspection, are sometimes classified into three levels critical, major and minor. Critical defects are those that render the product unsafe or hazardous for the end user or that contravene mandatory regulations. Major defects can result in the products failure, reducing its marketability, usability or saleability. Lastly, minor defects do not affect the products marketability or usability, but represent workmanship defects that make the product fall short of defined quality standards. Different companies maintain different interpretations of each defect type. In order to avoid argument, buyers and sellers agree on an AQL standard, chosen according to the level of risk each party assumes, which they use as a reference during pre shipment inspection. See alsoeditReferenceseditFurther readingedit.